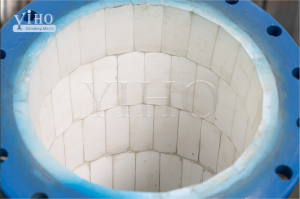

Ceramic Lined Wye Okuphakelayo Pipe & Tees

Ama-pipe wyes nama-pipe tee

Ama-pipe wyes afana nama-pipe tee.Umehluko kuphela ukuthi umugqa wegatsha u-engeli ukuze unciphise ukungqubuzana okungase kuphazamise ukugeleza.Ukuxhumeka kwepayipi kuvamise ukuba ku-engeli engu-45 degree kune-engeli engu-90 degree evamile.Uma igatsha liphenduka ekugcineni libe yi-perpendicular to the through the line, ukufakwa kwepayipi kuba "tee wye".

Izakhiwo Eziyinhloko Ze-Ceramic

| Isigaba | I-HC92 | HC95 | HCT95 |

| Al2O3 | ≥92% | ≥95% | ≥95% |

| ZrO2 | / | / | / |

| Ukuminyana | ≥3.60g/cm3 | ≥3.65g/cm3 | ≥3.70g/cm3 |

| Ukumuncwa Amanzi | ≤0.1% | ≤0.1% | ≤0.1% |

| I-HV 20 | ≥950 | ≥1000 | ≥1100 |

| I-Rock Hardness HRA | ≥82 | ≥85 | ≥88 |

| Ukugoba Amandla MPa | ≥220 | ≥250 | ≥300 |

| Amandla okucindezela i-MPa | ≥1050 | ≥1300 | ≥1600 |

| Ukuphuka Kokuqina kwe-KIc MPam 1/2 | ≥3.7 | ≥3.8 | ≥4.0 |

| Gqoka Ivolumu | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 |

Iphayiphi eyinhlanganisela ye-ceramic

Ukumelana okuhle kokugqoka

Ipayipi elihlanganisiwe le-Ceramic ngenxa ye-corundum ceramic (a-AL2O3), ubulukhuni be-Mohs obungu-9.0 bulingana nokungaphezu kwe-HRC90.Ngakho-ke, inokumelana nokugqokwa okuphezulu kwemidiya e-abrasive ethunyelwa yizimboni ezifana ne-metallurgy, amandla kagesi, izimayini, namalahle.Kuye kwaqinisekiswa ukusebenza kwezimboni ukuthi ukuphila kwayo kokugqoka izikhathi eziyishumi noma ngisho izikhathi eziningana eziyishumi kuneyensimbi eqinile.

Ukumelana okuncane kokusebenza

Ipayipi le-SHS Ceramic composite alifani nolayini oyi-convex spiral endaweni engaphakathi yepayipi lensimbi engenamthungo ngoba ingaphakathi libushelelezi futhi alilokothi ligqwale.Ubulukhuni bangaphakathi bendawo nezici ezicacile zokumelana namanzi zamayunithi afanele wokuhlola kwahlolwa.Ubushelelezi bendawo yangaphakathi yayingcono kunanoma iyiphi ipayipi lensimbi.I-coefficient yokudonsa ecacile yayingu-0.0193, eyayingaphansi kancane kunepayipi elingenamthungo.Ngakho-ke, ithubhu inezici zokumelana nokugijima okuncane futhi inganciphisa izindleko zokusebenza.

Ukugqwala, anti-scaling

Njengoba ungqimba lwensimbi lwe-ceramic luyi-(a-AL2O3), luyisici esingathathi hlangothi.Ngakho-ke, imelana ne-asidi ne-alkali kanye nokugqwala kwamanzi olwandle, futhi iphinde ibe nezindawo zokulwa nokulinganisa.

Ukumelana nezinga lokushisa nokumelana nokushisa

Ngenxa ye-corundum ceramic (a-AL2O3), iyisakhiwo sekristalu esizinzile esisodwa.Ngakho-ke, ipayipi elihlanganisiwe lingasebenza ngokujwayelekile ebangeni lokushisa lesikhathi eside -50--700 ° C.I-coefficient yokunwetshwa komugqa wento engu-6-8 × 10-6/0C, cishe u-1/2 wepayipi lensimbi.Impahla inokuzinza okuhle kwe-thermal.

Izindleko zephrojekthi ziphansi

Amapayipi ahlanganisiwe e-Ceramic anesisindo esincane futhi ayathengeka.Ilula ngo-50% kuneshubhu letshe elibunjiwe elinobubanzi obungaphakathi obufanayo;ilula ngo-20-30% kuneshubhu le-alloy elingagugi, futhi inokumelana nokugqokwa okuhle kanye nokumelana nokugqwala ngenxa yempilo yayo ende yesevisi, ngaleyo ndlela isekela izindleko ze-hanger, izindleko zokuhamba, izimali zokufaka, kanye Nokunciphisa izindleko zokusebenza.Ukuqhathanisa isabelomali sephrojekthi yesikhungo sokuklama kanye neyunithi yokwakha nephrojekthi yangempela, izindleko zephrojekthi zilingana netshe elikhonjiwe.Uma kuqhathaniswa nepayipi le-alloy elingagugi, izindleko zephrojekthi zincishiswa cishe ngama-20%.

Ukufakwa kalula nokwakhiwa

Ngenxa yesisindo sayo esincane nokusebenza kahle kwe-welding.Ngakho-ke, i-welding, ama-flanges, ukuxhuma okusheshayo, njll kungamukelwa, futhi ukwakhiwa nokufakwa kulula, futhi izindleko zokufaka zingancishiswa.

Isicelo

Izindololwane zamapayipi ane-Ceramic zingasetshenziswa ezingxenyeni zephampu kakhonkolo ngenxa yezinzuzo zazo, ikakhulukazi isisindo esiphansi, esiza ukugwema ukujamu ngesikhathi sokuthutha ukhonkolo.

Faka esikhundleni ipayipi lensimbi ye-carbon, ipayipi lensimbi engagqwali kanye ne-SDR

Ukukhishwa kwezinto ezigqoke kakhulu

I-Magnetite feed nemigqa yokukhipha amanzi

Ukugeleza komsila kungaphansi