Ukufakwa kwamapayipi anemikhono ye-Ceramic kusetshenziswe embonini yezimayini

Mayelana nokufakwa kwamapayipi anemikhono kaCeramic

Umkhono omkhulu we-ceramic we-ceramic uhlezi uyinkinga enkulu kubakhiqizi beshubhu le-ceramic njengoba kunzima kakhulu ukulawula izinga lokuguqulwa komkhono we-ceramic ngemva kokucwiliswa .Futhi Uzodinga futhi umshini wokucindezela we-isostatic othuthukisiwe nomkhulu ukwenza lokhu .Ngakho-ke ngeke nje iveze ikhono lokukhiqiza lenkampani, kodwa nobuchwepheshe benkampani.Njengamanje, imboni yethu inazo zombili izinzuzo okuyizindawo zokucindezela ze-ceramic ezigqokekayo kanye nobuchwepheshe.

Sihlangabezane nobunzima obuthile lapho sikhiqiza imikhono ye-ceramic futhi sasingatha zonke izinkinga ngemuva kwemizamo yabantu bethu bocwaningo kanye nobunjiniyela .Futhi sidale umshini wokufaka olula kakhulu ukwenza ukufakwa komkhono we-ceramic emapayipini njengoba umkhono unzima kakhulu. enkulu futhi esindayo .Ngemva kwenyanga sisebenza, siqede lesi sitsha esingu-20' esingu-95% se-alumina ceramic emikhono yamapayipi amapayipi , amapayipi T nezindololwane namakhasimende nabo baziswa kakhulu mayelana nokusabela kwethu ngokushesha kanye nemizamo emikhulu kule phrojekthi esetshenziswa ohlelweni lokudlulisa udaka lwezimayini. .

I-Sintering njengeshubhu le-ceramic eliphelele noma umkhono we-ceramic, bese uyihlanganisela epayipini lensimbi noma ipayipi lensimbi engagqwali nge-adhesive yethu ye-epoxy emelana namandla aphezulu.Ipayipi le-ceramic elinemikhono ye-ceramic lisetshenziswe kakhulu embonini yezimayini, njengepayipi lezimayini elidaka, ipayipi lokususa uthuli lwezimayini, ipayipi lezimayini elidlulisa i-slag, izindololwane kanye namapayipi we-T.

Lolu hlobo lwepayipi le-ceramic elifakwe umugqa liqukethe izingxenye ezintathu (ipayipi lensimbi + ingcina + amathayela e-ceramic), ipayipi lensimbi lenziwe ngepayipi lensimbi engenamthungo.Amathayili e-ceramic angama-95% aphezulu e-alumina, futhi ukubopha ukushisa okuphezulu kwe-epoxy adhesive kuze kufike ku-350oC.Lolu hlobo lwepayipi lufanelekile ukuthuthwa kwe-powder ngaphandle kokuwa kwe-tile noma ukuguga okusebenza ngaphansi kwe-350oC isikhathi eside.Impilo yesevisi izikhathi ezi-4 kuya kwezi-5 kunepayipi elivamile lensimbi.

Izifakelo zamapayipi anemikhono kaceramic Ububanzi bohlelo lokusebenza

Lawa mapayipi asetshenziswa kuma-Pneumatic and Hydraulic Systems ahlushwa ukugqoka okuphezulu, ukushelela okuphezulu kanye nomthelela omkhulu, ikakhulukazi ezindololwaneni.Singakwazi futhi ukuklama ukufakwa kwamapayipi ngokwezifiso ukuhlangabezana nezinhlelo zokusebenza ezahlukene.

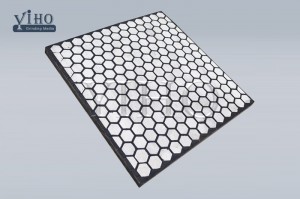

I-Ceramic Wear Tile Material & Izithombe

-92% Alumina

-95% Alumina

-99% Alumina

-RBSiC Silicon carbide

- Umugqa we-ZTA

| Isigaba | I-HC92 | HC95 | HCT95 | HC99 | I-HC-ZTA |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% |

| ZrO2 | / | / | / | / | ≥21% |

| Ukuminyana (g/cm3 ) | >3.60 | >3.65g | >3.70 | >3.83 | >4.10 |

| I-HV 20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 |

| I-Rock Hardness HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 |

| Ukugoba Amandla MPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 |

| Amandla okucindezela i-MPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 |

| Ukuqina Kokwaphuka (Kic MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 |

| Ivolumu yokugqoka (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 | ≤0.05 |