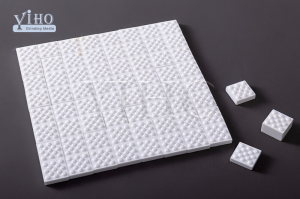

Imayini Yamalahle I-Ceramic Perforated Lining Plate Ithayela Elishiselayo

I-Ceramic Perforated Lining Plate Isingeniso Sethayela Esishiselayo

I-YIHO ihlinzeka futhi ifake uhla olubanzi lwamaThayela Amelana ne-Alumina Wear ukuze kuvikelwe ukugqokwa kwazo zonke izindawo ezifana nama-Chutes, amaSilo, Okuphakelayo, Imigqomo, Imigqomo, I-Dutching, Amathangi, Ama-Bunkers, Ama-Hoppers, Ama-Underpans njll.

Ichazwa njengezinto zesikhathi esizayo, izitsha zobumba ze-alumina zingenye yezinto zemvelo ezinzima kunazo zonke ezaziwa umuntu.Ngaphansi kwezimo ezilimaza kakhulu, akukho mpahla engaqhudelana ngezindleko zempilo nobulukhuni bayo obudlulele kanye nokumelana nokuguga.Ngaphezu kwalokho, i-alumina ceramics inamakhemikhali akhethekile, imishini, i-thermal kanye ne-electrical insulation properties futhi ingakhiwa ibe yinoma yisiphi isimo noma usayizi onezimfanelo ezihlukahlukene zezinhlelo zokusebenza ezithile.

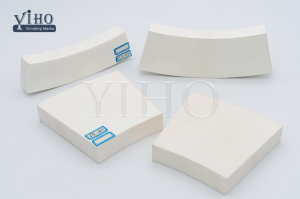

Amathayela e-Weld-On alumina ceramic ngokuvamile asetshenziswa ezinhlelweni zokushisa okuphezulu futhi atholakala ngamasayizi amaningi ukuze afanele uhlelo lwakho lokusebenza ngokwesisekelo sesitoko sangaphambili.

I-Ceramic Perforated Lining Plate Idatha Yezobuchwepheshe Yethayela Eshiselwayo

| Isigaba | I-HC92 | HC95 | HCT95 | HC99 | I-HC-ZTA | ZrO2 |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | ≥21% | ≥95% |

| Ukuminyana (g/cm3 ) | >3.60 | >3.65g | >3.70 | >3.83 | >4.10 | >5.90 |

| I-HV 20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| I-Rock Hardness HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Ukugoba Amandla MPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Amandla okucindezela i-MPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Ukuqina Kokwaphuka (Kic MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Ivolumu yokugqoka (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 | ≤0.05 | ≤0.02 |

Ceramic Perforated Lining Plate Weldable Tile Izinzuzo

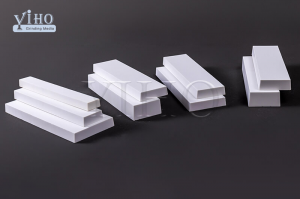

Amathayela we-alumina ashisekayo, aziwa nangokuthi amathayela we-alumina ceramic weld-on noma ama-ceramic weldable linings, anikeza izinzuzo ezimbalwa uma esetshenziswa ezinhlelweni ezimelana nokuguga.Lawa mathayela ajwayele ukusetshenziselwa ukuvikela okokusebenza kwasembonini kanye nezindawo ezingaphezulu kokuthi zingahuzuka, zibe nomthelela, futhi ziguge.Nazi ezinye zezinzuzo ezibalulekile zama-alumina tiles weldable:

1. Ukuqina Okuphezulu Nokumelana Nokugqoka: I-alumina ceramic ingenye yezinto ezinzima kakhulu, ehlinzeka ngokumelana nokugqoka okuhle kakhulu nokuqina.Amathayili ashiselayo enziwe nge-alumina alungele ukuvikela izinto zokusebenza nezindawo ezivezwe ezintweni eziqhumayo.

2. Ukumelana Kwamakhemikhali Nokugqwala: I-Alumina ayifaki amakhemikhali futhi imelana kakhulu nezinto ezigqwala, okuyenza ifanelekele ukusetshenziswa ezimbonini ezinendawo yamakhemikhali anolaka.

3. Ukumelana Nezinga Lokushisa: Amathayili we-alumina ashiselayo akwazi ukumelana nezinga lokushisa eliphezulu ngaphandle kokuwohloka okuphawulekayo kwezakhiwo zawo, awenze afanelekele izinhlelo zokusebenza ezihilela amazinga okushisa aphakeme noma ukushaqeka kokushisa.

4. I-Uniform Surface: Amathayili anikeza indawo ebushelelezi nefanayo, enciphisa ukwakheka kwezinto futhi aqinisekise ukugeleza kwezinto ezingaguquki, okubalulekile ezinqubweni ezithile zezimboni.

5. Ukufakwa kalula: Njengoba igama libonisa, amathayili ashiselayo aklanyelwe ukufakwa kalula kusetshenziswa amasu okushisela.Lokhu kuvumela ukunamathiselwa okusheshayo nokuvikelekile ku-substrate, ukunciphisa isikhathi sokuphumula ngesikhathi sokufakwa nokugcinwa.

6. Ukwakheka Nosayizi Okwenziwe Ngokwezifiso: Amathayili ashiselekayo e-Alumina angenziwa ngezindlela ezihlukahlukene nosayizi ukuze alingane nemishini ethile noma izindawo ezithile, anikeze ukuguquguquka ekwakhiweni nasekuqinisekiseni ukumbozwa okuphelele kwezindawo ezigugile.

7. Isikhathi Sokuphumula Esincishisiwe Sokulungiswa: Ngokuvikela izinto zokusebenza ezingaphansi ekugugeni nasekulimeni, amathayela we-alumina ashisekayo andisa ukuphila kokusebenza kwemishini, enciphisa imvamisa yokunakekela kanye nesikhathi sokuphumula.

8. Ukonga Izindleko: Nakuba amathayela we-alumina ashisela angase abe nezindleko eziphakeme zokuqala uma kuqhathaniswa nezinye izinto zokwakha, ukuphila kwawo okude kanye nezidingo ezincishisiwe zokunakekelwa kuwenza angabizi ngokuhamba kwesikhathi.

9. I-Electrical Insulating: I-Alumina iyisivikeli esihle kakhulu sikagesi, esiyenza ifanelekele izinhlelo zokusebenza lapho ukuqhutshwa kukagesi kufanele kugwenywe.

10. Ukuhambisana Nezisekelo Ezihlukahlukene: Amathayili we-alumina ashiselekayo angasetshenziswa kuma-substrate ahlukahlukene, okuhlanganisa insimbi, ukhonkolo, nezinye izinto zokwakha, okuwenza asebenziseke ngezindlela ezihlukahlukene ezinhlobonhlobo zezicelo zezimboni.

Sekukonke, amathayela ashisekayo we-alumina ahlinzeka ngesixazululo esinokwethenjelwa nesisebenzayo sezinhlelo zokusebenza ezingagugi, ahlinzeke ngokuvikeleka ekuhutsheni, emthelela, nasekuhlaselweni kwamakhemikhali.Ukuqina kwazo, ukubekeka kalula, kanye nokuphumelela kwezindleko zesikhathi eside kuzenza zibe yinketho ethandwayo ezimbonini ezinjengezimayini, usimende, insimbi, ukukhiqiza ugesi, nokuphatha izinto ezibonakalayo, lapho ukuguga kuyizinselele ezivamile.