I-Hot Vulcanization Rubber Ceramic Composite Wear Panels

I-Hot Vulcanization Rubber Ceramic Composite Wear Panel Isingeniso

Izixazululo ze-YIHO Wear Panel zilungele izinhlobonhlobo zezimayini, ukucutshungulwa kwamaminerali kanye nokuphathwa kwezinto ezibonakalayo ukuze kuvikelwe ekugugeni ngokweqile.

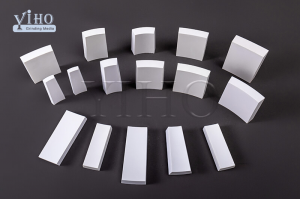

A. Inqubo ye-Ceramic nenjoloba yokuvuthwa ivuthiwe futhi inokwethenjelwa.

Ekwelapheni okungaphezulu kwe-ceramic ngaphambi kokwenziwa i-vulcanization, sisebenzisa ukungenisa kwe-US komenzeli wokwelapha ongaphezulu.Imikhiqizo ene-vulcanized Ngisho noma i-liner igobile i-360 °, i-ceramic ngeke iwe enjoloba.

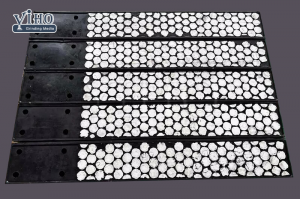

B. i-ceramic liner kanye nensimbi yokunamathisela ngokuqinile

Kulayini we-ceramic kanye ne-steel bonding, sisebenzisa insimbi evela kwamanye amazwe kanye ne-rubber adhesive.Umkhiqizo unokunamathela okuqinile, ukumelana nokushisa okuhle, ukumelana ne-asidi ne-alkali, ukumelana nokugqwala, ukulwa nokuguga nokunye.Njengoba inkampani yami i-ceramic rubber liner inamathisela okunamathelayo okukhethekile, cishe iminyaka eyishumi ukusetshenziswa kwamakhulu amakhasimende, ukwethembeka kuhle kakhulu, kuze kube manje, akukho mkhiqizo owodwa ngaphandle kwenkinga.

Izinga lokushisa elinamathelayo lezinto eziphilayo elingu-100 ℃, eliphansi kakhulu lokususa i-50 ℃.Isebenza kakhulu ku-ceramic composite liner paste, ngenxa yokunamathela okuqinile kwe-viscose ye-organic, kuyilapho indawo yokuxhumana ye-liner nemishini inkulu, ifaneleka kakhulu umthelela omkhulu, ukuguga okubucayi nokudabula kwesistimu yokudlulisa impahla, njengokuphatha amalahle esitshalo samandla. uhlelo, Steel, ukuncibilikisa sintering plant nokunye.

I-Hot Vulcanization Rubber Ceramic Composite Wear Panels Isicelo

Izibonelo ezijwayelekile zohlelo lokusebenza:

· Izitha

· Izishingishane

· Launders

· Amapayipi namathangi

· Amaphuzu okudlulisa umthumeli

· Imishayo yesikrini, izingubo zangaphansi nezingxenye

· Iziphakeli ezidlidlizayo

I-Hot Vulcanization Rubber Ceramic Composite Wear Panels Izici nezinzuzo ezibalulekile

Izici ezibalulekile nezinzuzo

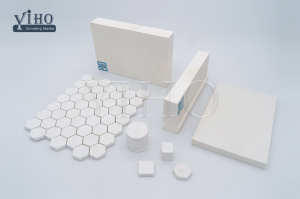

• 92% Aluminium oxide impahla.

• Inhlanganisela yerabha ehlanganiswe nama-CN polymers.

• Isendlalelo esibophezelayo se-CN nemiphetho ebhafiwe.

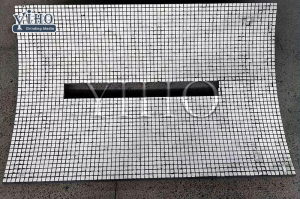

• Usayizi olawulekayo nesisindo.Ububanzi be-strip 250mm bukwenza kube lula ukuyifaka.

• Inhlanganisela yerabha engashi kanye ne-antistatic (FRAS) iyatholakala.

• Irabha yesibabule ephansi.

• Amathayili e-Ceramic ahlanganiswe nerabha macala onke (ngaphandle kwendawo engaphezulu).

• Ihlinzekwa ngamaphaneli ayizikwele 500mm x 500mm.

• Ukumelana nokugqoka ngokweqile.

• Ukunamathela okuvelele kumathayili e-ceramic, irabha nensimbi.

• Ukuze uthole ukunamathela okuphezulu okubandayo okunama-vulcanized.

• Ingasetshenziswa ezinhlelweni ezingaphezulu nangaphansi komhlaba.

• Ukuqina kwerabha okuzinzile ngokuya ngeminyaka.

• Imelana nokuqhekeka kwamathayili nokuwakhipha.

• Kulula ukufaka.

Irabha, Ceramic & Steel Ukucaciswa

| S.No. | Okubalulekile | Izimfanelo | Izakhiwo |

| 1 | Amathayela E-Ceramic | Okubalulekile | 92%, 95%, T95%,99%, ZTA |

| 2 | Irabha | Isakhi | Irabha yemvelo |

| Ukuminyana | 1.4g/cm3 | ||

| Amandla aqinile ngesikhathi sekhefu | ≥10.6Mpa | ||

| Ukwandisa ngesikhathi sekhefu | ≥350% | ||

| Ukuqina Kwasogwini | 45-65 | ||

| Ukunamathela phakathi kwethayela nerabha | ≥3.8 Mpa | ||

| I-Adhesive phakathi kwerabha nemishini | ≥3.58Mpa | ||

| I-Thermal conductivity.(izinga lokushisa elivamile) | 2w/m·k | ||

| Isikhathi sokuguga | ≥Iminyaka engu-15 | ||

| Izinga lokushisa lokusebenza | -50ºC -200ºC | ||

| 3 | Ipuleti lensimbi | Okubalulekile | Q235A |

| Ukuminyana | 7.85g/cm3 | ||

| Ubukhulu | 3-10 mm | ||

| 4 | Okunamathelayo | Ukubukeka | Uketshezi olunamanzi ansundu |

| Okuqukethwe okuqinile | 20±3% | ||

| I-Viscosity | ≥2.5 Mpa | ||

| Amandla e-peel | 48h N/2.5cm≥120 | ||

| Amandla acindezelayo | ≥850 Mpa | ||

| Izinga lokushisa lokusebenza | -20ºC -100ºC |