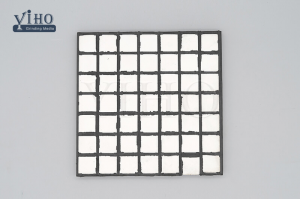

I-Hybrid Liner Rubber Ceramic Matrix

MAYELANA ne-Hybrid Liner Rubber Ceramic Matrix

Ihlanganiswe kusetshenziswa inqubo ekhethekile, iHybrid Liner ihlanganisa izinto ezimbili zamalayini kanye nezakhiwo zazo ezithandekayo.Ingaphakathi lenziwe nge-polyurethane futhi livikela isitho esisele nesitho samathambo ngenxa yezimpawu zalo ezidonsa ukushaqeka.Ngesikhathi esifanayo, iqinisekisa ukusatshalaliswa kwengcindezi ephezulu kuwo wonke umlenze osele, womabili wokwenza i-vacuum engenzi lutho futhi esebenzayo.Ingaphandle le-liner kanye ne-vacuum flap ehlanganisiwe yenziwe nge-silicone, efakazelwe ekusetshenzisweni kwansuku zonke ngenxa yokuqina kwayo.Lokhu kubaluleke kakhulu lapho i-vacuum flap igoqwa phezu kwesokhethi yangaphakathi ukuze kwakheke isivalo esingangeni moya sohlelo.

IHybrid Liner Rubber Ceramic Matrix Isicelo

Endabeni yokuhuzuka maqondana nemigqa yenjoloba, kufanele kucatshangelwe izitatimende ezilandelayo.

1- Kunezinhlobo ezimbili zokuhuzuka umuntu angase ahlangane nazo, ukubopha kanye nokushelela.

2- Ukuhuzuka kokuqina kwenzeka lapho izinhlayiya zishaya ingaphezulu lerabha (noma enye indawo).

3- Ukuhuzuka kokuslayida kwenzeka lapho enye indawo islayida kuyo yonke irabha.

4- Cishe kuzo zonke izimo ukuhuzuka kungalindelwa ukuthi kube inhlanganisela yokufaka nokushelela.

5- I-impingement abrasion ivame ukuvela kumachute, ipayipi le-sandblast nanoma yikuphi lapho kubukwa khona i-rebound.

6- Enqubweni yokufaka, izinhlayiya zishaya phezulu futhi noma yikuphi ukucindezeleka okukhiqizwayo kusakazwa ngokulinganayo uma irabha ikhiqiza kalula, ikakhulukazi uma izinhlayiya zishaya nge-engeli engu-90° phezulu.

Izinto Zobumba (I-Alumina + I-Reaction Bonded Silicon Carbide Tiles)

| Isigaba | 92% Al2O3 | 95% I-Al2O3 |

| ZrO2 | / | / |

| Ukuminyana(gr/cm3) | >3.60 | >3.65g |

| I-HV 20 | ≥950 | ≥1000 |

| I-Rock Hardness HRA | ≥82 | ≥85 |

| Ukugoba Amandla MPa | ≥220 | ≥250 |

| Amandla okucindezela i-MPa | ≥1050 | ≥1300 |

| Ukuqina Kokwaphuka (Kic MPam 1/2) | ≥3.7 | ≥3.8 |

| Ivolumu yokugqoka (cm3) | ≤0.25 | ≤0.20 |

| I-Silicon CarbideIdatha(RBSiC) | ||

| Inkomba | Inani | Umphumela wokuhlolwa |

| Sic | / | ≧90 |

| Izinga lokushisa | ℃ | 1380 |

| Ukuminyana Okuthile | g/cm3 | ≧3.02 |

| Vula i-Porosity | % | <0.1 |

| I-Modulus ye-elasticity: | I-Gpa | I-330Gpa (20 ℃) 300Gpa(1200 ℃) |

| Ukuqina kukaMoh | / | 9.6 |

| Amandla okugoba | Mpa | 250(20℃)/ 280 (1200℃) |

| Amandla Wokucindezela | Mpa | 1150 |

| I-coefficient yokunwetshwa kwe-thermal: | / | 4.5K^(-3)*10^(-5) |

| I-coefficient ye-thermal conductivity: | W/mk | 45 (1200℃) |

| I-Acid Alkaline -ubufakazi | / | Kuhle kakhulu |