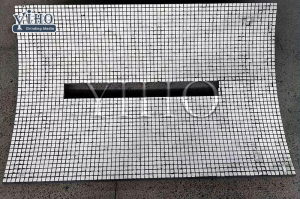

Ithayela lekhona le-alumina langaphambi kobunjiniyela

Isethulo sethayela lekhona le-alumina langaphambi kobunjiniyela

Gqoka uthayela wobunjiniyela obungazweli ezinhlobonhlobo zomumo wejiyomethri kusukela kokulula kuye kokuyinkimbinkimbi, izitsha zobumba zingakhiwa noma zibunjwe kuye komumo othize ngokwesidingo sekhasimende.

Imishini kaceramic efakwe ulayini njengamapayipi, ukugoba, ama-chute, ama-hopper, ama-bunkers, njll. I-alumina ceramic liner inokumelana okuhle kakhulu nokuhuzuka, ukumelana kanzima, ukumelana nokugqwala, isetshenziswa kakhulu ezimayini, imboni yamandla, imboni yensimbi, izimboni zikasimende njengama-chute, i-hopper ,i-bunker, i-cyclone, ibhande lokudlulisa, njll. Lo mkhiqizo we-alumina ceramic wenza ukusebenza okungabizi kakhulu njengokunciphisa isikhathi sokunciphisa okungadingekile nokunakekelwa, nokwelula okokusebenza ekuhuhukeni okusheshayo.

Umkhiqizo wama-linings onjiniyela uyisipesheli. Singahlinzeka futhi sifake izinhlobonhlobo zamathayili e-alumina enziwe ngobunjiniyela be-alumina enziwe ngokwezifiso ukuze afanele noma yiluphi uhlobo lohlelo lokusebenza.Isofthiwe ye-CAD isetshenziselwa ukuklama ulayini ongagugi wezingxenye zekhasimende.Ukwenza imishini ngaphambi kokucwenga kusenza sikwazi ukunikeza ama-lining anomumo oyinkimbinkimbi kanye nobukhulu obu-3 njengesixazululo esingabizi kakhulu.Okuzolingana cishe nanoma iyiphi i-geometry, Uhlelo oluklanywe kahle lwe-lining lonjiniyela oluhlukile ezitini ezijwayelekile zamathayela e-ceramic luzokwenza imishini ibe ne-engeli ekhethekile ngaphandle kwegebe, ngakho igwema ukumoshwa kwezinto kanye nokulimala kwemishini.

Izakhiwo zethayela lekhona le-alumina langaphambi kobunjiniyela

| Isigaba | I-HC92 | HC95 | HCT95 | HC99 | I-HC-ZTA | ZrO2 |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | ≥21% | ≥95% |

| Ukuminyana (g/cm3 ) | >3.60 | >3.65g | >3.70 | >3.83 | >4.10 | >5.90 |

| I-HV 20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| I-Rock Hardness HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Ukugoba Amandla MPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Amandla okucindezela i-MPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Ukuqina Kokwaphuka (Kic MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Ivolumu yokugqoka (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 | ≤0.05 | ≤0.02 |

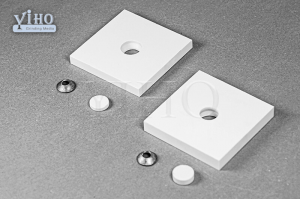

Isici sethayela lekhona le-alumina yobunjiniyela bangaphambili

· Isakhiwo esihle kakhulu sokumelana nokugqwala

· Usayizi nesisindo esisingathwa kalula

· Isakhiwo esihle kakhulu sokumelana nokushisa

· Isakhiwo esihle kakhulu sokumelana nomthelela

· Ukufakwa okusheshayo nokuphephile

· Izindleko eziphansi zokukhiqiza nokulungisa

Kungani Khetha ithayela lekhoneni le-Yiho Pre-engineering alumina

· Ithimba lochwepheshe lobuchwepheshe ukukhokhela imiklamo ye-CAD

· Ithimba lokufakwa kochwepheshe ukuze likwazi ukukhokhela isevisi yokufaka

· Inqubo esungulwe kahle ngokwezindinganiso zamazwe ngamazwe

· Yamukela amathayela ajwayelekile naklanywe ngaphambilini

Uhlobo lwe-YIHO lwamathayela e-ceramic Plain

- Ithayela le-Alumina elilula

- Ithayela lepayipi

- Ithayela le-radius

- Ithayela eligobile

-Ithayela elishiselayo/elishiselwe

- tile eyenziwe

P kabusha ubunjiniyela bethayela lekhona le-alumina Isicelo

Amathayela ekhoneni le-alumina ceramic wear angamathayili akhethekile aklanyelwe ukuvikela nokuqinisa amakhona nemiphetho yezinto zokusebenza, izakhiwo, nezindawo ezivame ukuguga, ukuhuzuka, nomthelela.

Ama-Chutes nama-Hoppers

Ukudluliswa kwe-Conveyor

Ama-Clinker Chutes namaKilns