Gqoka Izindwangu Zesishingishane Ezingazweli Ezenziwe Nge-Alumina

Incazelo enemininingwane

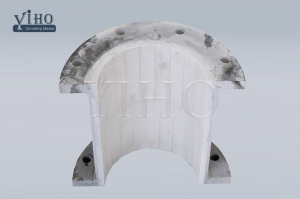

Umzimba oyinhloko wesishingishane uqukethe isinciphisi noma ulayini omise okwekhoni osuka kububanzi obukhudlwana ukuya kwencane kwehle ngobude bawo.

Wear Resistant Solutions for Cyclones

Njengoba izinto ezihlukaniswa yisiphepho zilimaza kakhulu, kubalulekile ukuthi kube nomugqa wesiphepho omelana nobunzima bomsebenzi.I-Ultra High Purity Alumina ingasetshenziswa ukukhulisa impilo yokusebenza nokusebenza kwesishingishane futhi ingabunjwa ngokwezifiso ukuze ivumelane nawo wonke amajiyometri;kusukela emsebenzini wepayipi oholela endaweni yokungena, isitholi se-vortex kanye ne-apex outlet, enhliziyweni ye-conical yesiphepho.

Izingxenye Ze-Cyclone Ngokuvamile Zingaphansi Kokugqokwa

Kunezingxenye eziningi ngaphakathi komhlangano we-cyclone ezingaphansi kwezimo zokugqoka eziphezulu.I-Taylor Ceramic Engineering ingahlinzeka okuningi kwalokhu ezintweni ezingagqoki ukuze kunwetshwe impilo yengxenye.Ezinye zezingxenye esizihlinzekayo ngokuvamile zihlanganisa:

· Ama-Cylindrical & Reducing Liners

· Izindlu zokungena

· Izitolo

· Spigots

· Ifaka

· Izigaba Zekhoni Engenhla, Ephakathi Nephansi

· Izitholi ze-Vortex

· Cishe noma iyiphi indawo egugayo!

Gqoka Amafomethi Oqweqwe Olungazweli

Kungasetshenziswa uhla lwamasu olwelwesi olungagqoki;kusukela ekufakweni kwe-monolithic kuya ezingxenyeni zamathayela.

Izigaba ze-Monolithic

I-YIHO ibekwe ngendlela ehlukile ukuze ikwazi ukwenza izimo ezincane nezinkulu ze-monolithic ngamafreyimu esikhathi esifushane.Lezi zigaba zingenziwa ngokwezifiso ukuze zivumelane nezidingo zakho ezinembile.

Izigaba ze-Monolithic zinenzuzo yokuthi zishesha kakhulu ukuzifaka, ngaleyo ndlela zinciphise isikhathi sokuphumula.

Izigaba Ezifakwe Amathayela

Ngenxa yokuthi izindawo eziningi ezihlotshaniswa nomhlangano wesishingishane zigobile, i-Taylor Ceramic Engineering iyakwazi ukuklama amathayela ahambisana nokuma okudingakalayo.

Amathayela ayisicaba ezindaweni ezigobile ngokuvamile ashiya uchungechunge lwamafulethi ngokukhazimula endaweni engaphakathi yesishingishane.Lokhu akuphazamisi ukugeleza kwezinto ezibonakalayo kuphela kodwa kwandisa ukuguga ezindaweni ezifakwe amathayela futhi ngaleyo ndlela kunciphisa impilo yemishini.Kodwa-ke, ukusebenzisa amathayela agobile abunjiniyela ahambisana nesimo esidingekayo kunciphisa ukungaqhubeki futhi kukhulisa ukugeleza kwezinto futhi ngaleyo ndlela nokusebenza kahle kwemishini.

| Isigaba | HC90 | I-HC92 | HC95 | HCT95 | HC99 | I-HC-ZTA | ZrO2 |

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Ukuminyana | ≥3.50g/cm3 | ≥3.60g/cm3 | ≥3.65g/cm3 | ≥3.70g/cm3 | ≥3.83g/cm3 | ≥4.10g/cm3 | ≥5.90g/cm3 |

| Ukumuncwa Amanzi | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% |

| I-HV 20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| I-Rock Hardness HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Ukugoba Amandla MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Amandla okucindezela i-MPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Ukuphuka Kokuqina kwe-KIc MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Gqoka Ivolumu | ≤0.28 cm3 | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |