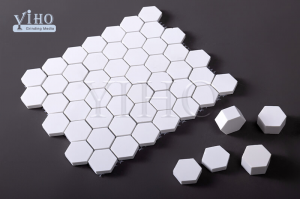

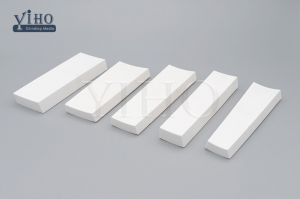

Amapuleti okugqoka e-Ceramic okuhuzuka okunonya

Gqoka amapuleti ezindaweni ezidinga kakhulu

Ipuleti lokugqoka le-Ceramic linokumelana okuphezulu kakhulu nokuhuzuka komshini nokuguguleka.Asetshenziswa ngokunenzuzo njengezinto zokwakha ezindaweni zokulahla amaloli nezikebhe ezilayisha futhi zithulule amatshe ambiwa namadwala, ukuphatha izinsalela zensimbi ezisindayo kanye nomsebenzi wokubhidliza lapho kukhishwa khona ukhonkolo onezinsimbi zokuqinisa insimbi embhedeni oyisicaba.

Izinga lomsindo eliphansi

I-ceramics yamapuleti ifakwe ohlakeni lwensimbi noma i-vulcanized ku-raber, okwandisa ukumelana nomthelela futhi kunciphise izinga lomsindo ngenxa yezakhiwo zokudonsa ukushaqeka kwerabha.Zingabotshwa noma zinamathiselwe ngqo ebusweni bepuleti lokugqoka.

Ukukhiqiza ngokuya ngokucaciswa

I-Yiho ihlale iletha isixazululo esilungiselelwe lapho amapuleti ethu e-ceramic enziwa ngokuya ngokucaciswa kwamakhasimende.Kucatshangelwa, phakathi kwezinye izinto, ukusetshenziswa nokugeleza kwezinto ezibonakalayo, uhlobo lwe-ceramic, ubukhulu nobukhulu, ngokufakwa noma ngaphandle kokufakwa kwerabha, njll.

I-Ceramic Material: I-Silicon Carbide

I-Silicon Carbide (SiC)

I-silicon carbide yenziwa ngezindlela ezimbili, ukuhlanganisa ukusabela kanye ne-sintering.Indlela ngayinye yokwakha ithinta kakhulu i-microstructure yokugcina.

I-Reaction bonded SiC yenziwa ngokufaka ama-compact enziwe ngezingxube ze-SiC nekhabhoni ene-silicon ewuketshezi.I-silicon isabela nekhabhoni yakha i-SiC eyengeziwe ebopha izinhlayiya zokuqala ze-SiC.

I-Sintered SiC ikhiqizwa ngempushana ye-SiC emsulwa enezinsiza-kusinta ezingeyona i-oxide.Izinqubo ezivamile zokwakheka kwe-ceramic ziyasetshenziswa futhi i-material ifakwa endaweni epholile emazingeni okushisa afika ku-2000ºC noma ngaphezulu.

Zombili lezi zinhlobo ze-silicon carbide (SiC) zimelana kakhulu nezinsimbi ezinhle, kufaka phakathi amandla okushisa aphezulu kanye nokumelana nokushaqeka okushisayo.Onjiniyela bethu bahlala betholakala ukuze bakweluleke kangcono ngamandla nobuthakathaka be-ceramic ngayinye ngezidingo zakho ezithile.

Izici ezijwayelekile ze-silicon carbide zifaka:

• Ukuminyana okuphansi

• Amandla aphezulu

• Amandla amahle okushisa okuphezulu (ukusabela kuhlanganisiwe)

• Ukumelana ne-oxidation (ukusabela kuhlanganisiwe)

• Ukumelana nokushaqeka okuhle kakhulu okushisayo

• Ukuqina okuphezulu nokumelana nokugqoka

• Ukumelana kwamakhemikhali okuhle kakhulu

• Ukunwetshwa okuphansi kwe-thermal kanye ne-high conductivity ye-thermal

Izicelo ezijwayelekile ze-silicon carbide zifaka:

• Izingxenye ze-turbine ezilungisiwe nezinyakazayo

• Izivalo, ama-bearing, ama-vane amaphampu

• Izingxenye ze-valve yebhola

• Gqoka amapuleti

• Ifenisha yokushisa

• Izishintshi zokushisa

• Imishini yokucubungula i-wafer ye-semiconductor

Ukuze uthole ulwazi olwengeziwe nge-silicon carbide yethu nokuthi lokhu kungasetshenziswa kanjani emkhiqizweni wakho, xhumana nathi namuhla