Ipuleti le-Alumina Wear elicindezelwe elomile

Mayelana ne-YIHO Alumina Wear Plate

Khulisa impilo nokusebenza kwezimpahla zakho zokusebenza.

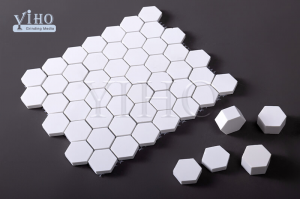

Ama-Wear Plates aklanywe futhi enzelwe ukusetshenziswa kwawo okuqondile okuhlosiwe, ukuqinisekisa ukuthi ipuleti elilungile lihlale lituswa futhi lifakiwe.

Ngokungeziwe ekuthengisweni kwamapuleti okugqoka, i-HICTECH inikeza amandla okufaka aletha ukwaneliseka kwamakhasimende okukhethekile kanye nenani.Sigqugquzelwa uphiko lwethu lwesevisi olunolwazi noluthembekile, sizolawula yonke iphrojekthi yakho, kusukela ekukhulelweni nasekuhlolweni, kuye ekukhiqizweni, ekulethweni, ekufakweni, ekulungisweni nasekuqhubekeni kwenkonzo/ukwesekwa kokuthengisa.

Amapuleti e-Wear akhiwe ukuze afanele uhlelo ngalunye futhi anezinketho ezihlukahlukene zokulungisa, amapuleti asekela insimbi, i-weld on options kanye ne-substrate bonding eqondile.

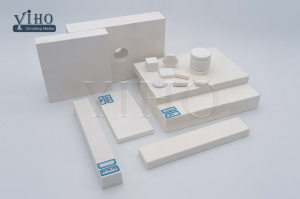

Alumina Ceramic Wear Plates

Ama-Wear Plates akhiqizwa ngokwezinga eliphezulu kakhulu kanye nokucaciswa kwawo, okuwenza abe phezulu kakhulu kunomunye umkhiqizo osemakethe.

Izici

• Izici zokugqoka eziphezulu

• Dampens umthelela

• Ukunciphisa umsindo

• Yehlisa isikhathi sokuphumula

• Izindleko eziphansi nge-ROI ngayinye

• Ifanele inhloso

Izicelo ze-Alumina Wear Plate

• Amaqhuqhuva

• Ama-Hopper

• Dlulisa amaphuzu

• Ukuchotshozwa nokuhlolwa

• Ukugaya

• Izilayishi zesitimela nomkhumbi

I-Alumina Wear Plate Specification

| Ukwakheka | Ubukhulu | Ukuminyana |

| Zirconia Toughened Alumina | 12mm, 25mm, 50mm | 4.2g/cm3 |

| I-Alumina 92% / 95% Al203 | 3-75 mm | 3.65&3.72gr/cm3 |

| I-Alumina 92% Al203 / Irabha Yemvelo | 8mm-63mm | / |

| I-Alumina 92% Al203 / High Tensile Polymer | 10mm-63mm | / |

| I-polyurethane | 3mm-20mm | / |

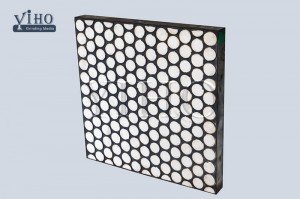

Ukufakwa komugqa wokugqoka we-ceramic

1. Ukunamathisela okunamathelayo okuqondile: sebenzisa izinga lokushisa legumbi noma izinga lokushisa eliphezulu eliqinile lokunamathisela okunamathelayo kwe-inorganic ukuze ukufake.Kulula ukuyifaka futhi ilungele umthelela omncane ngezinga lokushisa elingaphansi kuka-350 ℃.

2. I-Stud welding: ingasetshenziselwa izinto zokushisa eziphezulu kanye nezinto ezinamandla amakhulu.I-mechanical self-locking force kanye ne-inorganic adhesive ingaqinisekisa ukuthi i-liner ayiwi.

3. Ukufakwa komugqa we-ceramic owenziwe ngaphambilini: i-ceramic idinga ukufakwa epuletini lensimbi okokuqala ukuze kwenziwe i-ceramic liner engu-2-in-1 (ipuleti le-ceramic + lensimbi), noma liner ye-ceramic engu-3-in-1 (ipuleti le-ceramic + irabha + lensimbi) , bese kuthi ngokusebenzisa ama-welding noma ama-countersunk bolts ukuyifaka emishini, okulula ukuyilungisa nokushintsha.

I-High Purity Alumina ye-Ceramic Lining Plate ekwazi ukumelana nomthelela nokungezwani

ingangena esikhundleni somugqa wensimbi we-manganese, ongaxazulula ngokuyisisekelo inkinga yokuguga.Ilayini yokugqokwa ekwazi ukumelana nokushisa okuphezulu ishiselwa ezintweni zokusebenza nge-stud welding ye-ZTA ewugqinsi oqinile, ukuze kwakheke ungqimba oluqinile lokungagqoki.Amanye amaqhubu ayindilinga angaklanywa olayini ukuze athuthukise ukumelana kwawo komthelela.Ukuze kube lula ukufakwa nokushintshwa, i-ceramic liner ingafakwa epuleti lensimbi bese igxunyekwa ezintweni zokusebenza ngokushisela noma ngamabhawodi aphikisayo.