I-Engineering Wear Ceramic Matrix

Mayelana ne-Wear Ceramic Matrix

Ukuhuzuka kuhlala kungenakugwenywa ekucutshungulweni nasekuthuthweni kwezinto eziyinqwaba.Ukugeleza kwezinto eziwayo kubangela umthelela onamandla ikakhulukazi.Sinikeza amakhasimende ethu izixazululo ezingcono kakhulu nge-matrix yokugqoka yobumba yekhwalithi ephezulu (ene/ngaphandle kwepuleti lensimbi nebhawodi), ukuze sithole umphumela oncomekayo ekwandiseni ukumelana nomthelela kanye nokunciphisa ukuhuzuka nomsindo.

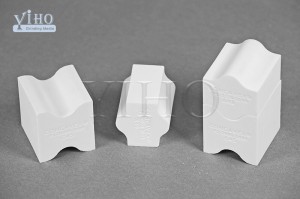

I-Ceramic Conveyor Wear Liners izokwehlisa kakhulu izindleko zakho zokusebenza uma iqhathaniswa nanoma iyiphi enye impahla yolayini.

I-Yiho ikhiqiza amalayini okugqoka amaconveyor ahlukahlukene ngoMeyi ongakhetha kuwo namasayizi ongakhetha kuwo.Idizayinelwe ukuphatha noma yiluphi uhlelo oluqinile lwezimayini zamadwala.Ukumelana nemihuzuko, okumodulayo, okugqokwa kakhulu kuma-chute amabhande, kanye nezindawo ezithinta umgqomo.

Gqoka Izici ze-Ceramic Matrix

* Ukumelana nomthelela omkhulu kakhulu

* Ama-coefficients wokungqubuzana aphansi

*Ukunciphisa umsindo

* I-montage elula futhi esheshayo

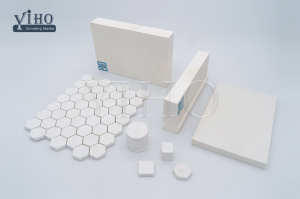

Uhlobo lweCeramics

Isilinda| I-Hex Tile | Unxande |Isikwele | Ikhibhu

92%, 95%, 99% Al2O3, ZTA, RBSIC Silicon Carbide

Idatha Yezobuchwepheshe:

| Isigaba | I-HC92 | HC95 | HCT95 | HC99 | I-HC-ZTA |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% |

| ZrO2 | / | / | / | / | ≥21% |

| Ukuminyana (g/cm3 ) | >3.60 | >3.65g | >3.70 | >3.83 | >4.10 |

| I-HV 20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 |

| I-Rock Hardness HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 |

| Ukugoba Amandla MPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 |

| Amandla okucindezela i-MPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 |

| Ukuqina Kokwaphuka (Kic MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 |

| Ivolumu yokugqoka (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 | ≤0.05 |

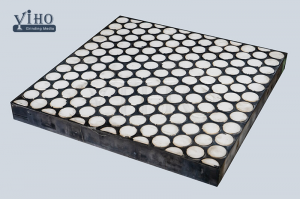

Uhlobo lwe-Wear Matrix

* Irabha esekelwe i-ceramic matrix

* I-matrix yerabha esekelwe ngensimbi ye-ceramic

Ubukhulu be-Ceramic Wear Matrix

Okuvamile&Okwenziwe ngokwezifiso,

Ubukhulu L800*W800mm

Izimboni zibandakanya i-Ceramic Wear Matrix

• Hlanganisa

• Itiyela

• Usimende

• Amakhemikhali

• Kushiswe Amalahle

• Amandla

• Amalahle

• Iyacubungula

• Ukudonsa

• Umanyolo

• I-Fiberglass

• Fly Umlotha

• Ukudla

• Iyacubungula

• I-Foundry

• Isihlabathi se-Frac

• Ingilazi neFrit

• Okusanhlamvu

• I-Gypsum

• Insimbi Nensimbi

• Amaminerali

• Iyacubungula

• Izimayini

• Izihlabathi zamafutha

• Uwoyela Negesi

• I-Petrochemical

• I-Potash

• I-Pulp & Iphepha

• Inkwali

• Ukugaywa kabusha

• Uphahla

• Izinto zokwakha

• Sand & Gravel

• Ushukela

• Amanzi angcolile

• I-Powder/Impahla Eningi

• Ukuphatha

• Izimakethe Zisetshenziswa

• Iyatholakala

Izicelo ze-Ceramic Wear Matrix

• I-Ash Slurry Lines

• I-Ball Mine Liners

• Izikulufo zokuphakela kwamagxolo

• Amagxolo Okuphatha Amagxolo

• Ibhokisi Emuva Izindololwane

• Ama-Clinker Hoppers

• Izikebhe zamalahle

• Ukuguqulwa Kwesithunywa

• Izishingishane

• I-Draft Liners

• I-Dust Collector Liners

• I-Exhaust Fan

• Izindlu

• Phuma Emapayipini

• Okuphakelayo Chutes

• Izindololwane Ezingemuva Eziyisicaba

• Imigqa Ye-Gas Scrubber

• Ukuphathwa Kwamafutha Engulube

• Izindlu zabalandeli baka-ID

• Izindlu Zomzimba Wokugaya

• Ore Bunkers

• Imizimba yePulverizer

• I-Pulverizer Classifier

• Izigaxa

• Ukukhipha i-Pulverizer

• Amavalvu

• I-Rock Bed Wall Liners

• AmaSilo namaBunkers

• Uguquko

• Iloli neRail Car

• Izindawo zokulahla amalahle

• Amabhokisi Owasha

• Izikulufu ze-Wennberg