Umkhiqizi oqondile ongu-92% kanye no-95% we-Al2O3 isitini se-ceramic lining ball mill

I-Liner Alumina Ceramic

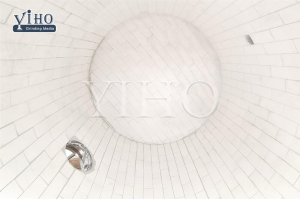

I-Yiho isebenzisa ikhwalithi ephezulu, i-colle-grain 92% / 95% isitini se-alumina esinolimi nomklamo we-groove.Izitini zivikelekile futhi zigaywe ngosimende we-Portland omsulwa noma i-epoxy enezingxenye ezimbili.Uma sekuyisikhathi sokubuyisela kabusha umshini wokugaya lokho futhi yisikhathi esihle sokuhlola ama-bearings kanye nezingxenye zokushayela.

Isicelo se-Alumina Ceramic Ball Mill Lining

Izitini ze-alumina lining zisetshenziswa njengolwelwesi embonini yebhola ye-ceramic, imboni ye-insulator.Ukusebenzisa le liner kuzothuthukisa ngempumelelo ukugaya, ukunciphisa izindleko zokugaya, futhi kubhekwa njengokukhetha kwakho okuhle kakhulu.

I-Alumina Liner ye-Batch Mill kanye ne-Continuous Mill: Ugqinsi olujwayelekile 40 kuya ku-90 mm.ngokuqukethwe kwe-Al2O2 92 kuya ku-95%.

Imboni: I-Ceramic & Insulator

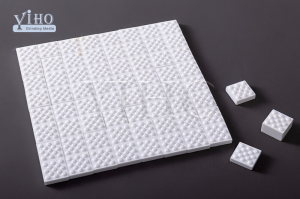

Ukucaciswa kwe-Ball Mill Brick

| Igama | Ubude (mm) | Ububanzi 1 (mm) | Ububanzi 2 (mm) | Ubukhulu (mm) | |

| 40 ~ 90mm Ukuqina Kwesitena Solayini | Isitini esiwunxande | 150±2 | 50±1 | 50±1 | 40/50/60/70/77/90±1 |

| Isitini seTrapezoidal | 150±2 | 50±1 | 45±1 | 40/50/60/70/77/90±1 | |

| Isitini esiwunxande esingunxande | 75±1 | 50±1 | 50±1 | 40/50/60/70/77/90±1 | |

| Isitini se-Trapezoidal Half | 75±1 | 50±1 | 45±1 | 40/50/60/70/77/90±1 | |

| I-Flake Brick | 150±2 | 25±1 | 22.5±1 | 40/50/60/70/77/90±1 | |

| Izitini zokubeka ulwelwesi olukhethekile | 80x50x55 | 55±2 | 50±1 | 50±1 | 80±1 |

| 110mm Ling Brick | 75±1 | 45±1 | 41±1 | 110±2 | |

| 110mm iHalf Ling Brick | 37.5±1 | 45±1 | 41±1 | 110±2 | |

| Isitini se-Manhole kanye ne-Drain-hole | Ukucaciswa kungenziwa ngokuya ngezidingo zamakhasimende. | ||||

I-Alumina Ceramic Lining APPLICATION

| Gqoka IZITINA ZE-CERAMIC EZINGAMELELE | |

| Isitini se-alumina sisetshenziselwa ukunciphisa ukuguga ezinhlobonhlobo zezicelo ezimbonini ezilandelayo: | |

| Isizukulwane Samandla Esiqhunyiswa Ngamalahle Ezinye zezinqubo ezidinga kakhulu zidinga izitsha zobumba ze-Alumina ezingagqoki ezisezingeni eliphezulu ezitholakalayo.Ukwakheka kwe-Alumina kwe-YIHO kuklanyelwe ngokukhethekile ukunikeza ukuvikeleka okuphezulu kakhulu kulezi zindawo zokugqokwa ngokwedlulele.Impilo yesevisi yezindawo ezisebenzisa i-alumina ephezulu ye-YIHO inganyuka izikhathi ezingaba ngu-10.

Imayini & Amaminerali Processing Ekumbiweni nasekucutshungulweni kwesihlabathi se-silica, amalahle, insimbi nensimbi eyigugu amanani okugqoka angaba phezulu kakhulu.Usebenzisa i-DURALBIT yobunikazi be-Bitossi ungakwazi ukunweba impilo yesevisi yezinto zokusebenza futhi unciphise isikhathi sokuphumula ngokufaka i-ceramic ezindaweni ezigugile kakhulu.Singanikela ngezinhlobonhlobo zosayizi nobujamo be-ceramic, amaphaneli e-ceramic, ama-hex-tiles, nobujamo bangokwezifiso.

Ukuphatha Okusanhlamvu Eziteshini zokugcina nokudlulisa emhlabeni wonke ama-ceramic resistant linings afakwe ukuze kuncishiswe ukuguga okubangelwa ukuhamba ngesivinini esiphezulu kommbila, irayisi, ukolweni, ubhontshisi wesoya, nekhofi.Ochwepheshe bethu bangasho ukuthi ungathola kanjani ukusebenza kahle okuphezulu kusetshenziswa i-ceramic wear resistant linings. I-Pulp & Paper Processing Okusanhlamvu okuhle kwe-YIHO 92%/95% I-Alumina Ceramic iyinto ekahle evikela izindawo eziningi kunqubo yokwenziwa kwe-pulp nephepha.I-Alumina Ceramic inikeza indawo ekwazi ukumelana nokugqwala nokuguga engeke ingcolise izixazululo zamakhemikhali ezisetshenziswa ekwenzeni iphepha. Ukwenza Insimbi Nensimbi I-alumina ceramics iyimpahla efanelekile yokweqa izimoto, ama-chute, ama-hopper, izindlu zabalandeli, amapayipi namapayipi okuphakelayo. |